Paper Mill Couch Suction Roll Spool Pope Reel Wire Guide Jumbo Bline Drill Paper Making Machine Roll

Product Description

Introduction to Paper Machine Suction Roll

1.1 Suction Roll

Manufacture details

Concept

Installation at the end of Flat Table with a Vacuum Zone and size limiter according to the width of the paper.

The Suction Roll will be build to allow the exchange of the Screen by the Cantillever system (Elongated shaft end for the drive side and spacer alongside the control).

The vacuum exit will be built alongside control of the machine on a stainless steel channel with removable aluminum shim.

Perforated face of sleeve: 3100 mm

Total sleeve length: 3260 mm

Roll diameter: 700 mm

Gram weight: 90 a 180 g/m2

Paper: Cover and interior

Working Speed: 180 a 600 m/min.

Screen maximum linear stress: 6 KN/m

Vaccum opening 6”

Manufacturing Features of the Roll.

Sleeve:

Made of calendered stainless steel with perforation distributed according to the machine speed and paperweight.

Imported sleeve.

Suction box:

It will be entirely in AISI 304 stainless steel, welded and machined for the perfect fit of the central pin inside the shaft end. With its sealing components (grooves, adjustment arms, spindles, tanyl support rollers, etc.)

In the upper part, channels made of brass fixed on the box to support the hoses and sealing strips.

The adjustment of the box IS possible by a spindle and endless screw.

The sealing strips are made of graphite material MGU1 / 2B by Carbono Lorena, which seal the suction zone upon the rotating sleeve.

Between the guides and the graphite strips are chambers of compressed air rubbers made of “vincon”, which when pressed tightens the sealing strips upon the sleeve. The compressed air connection is located on the control side, installed in the front head.

“Lubrification Shower”:

Attached to the suction box to lubricate the sleeve sealing strip. The shower forms a thin layer of water on the inside of the sleeve, which helps in sealing the suction zone. All the shower and other connections are made of stainless steel.

“Air shower”:

To assist the passage of the tip we place an internal air shower driven by a Valve on the control side.

“Cleaner Shower”:

Including the assembly of an internal shower to clean the sleeve.

Front Panel:

With vacuum gauge, air and water inlets, grease and position indicator with mirrored stainless steel plates.

Shaft ends:

Made of GGG-40 nodular cast iron and fixed directly to the sleeve. The shaft ends will be machined to receive spherical roller bearings, and the shaft end on the drive side will be stretched to adapt the Cantillever system support.

The removal of the bearings shall be made through hydraulic extraction.

Format limiter

Internal system that allows the width adjustment of the suction box, moved by spindles, this adjustment being independent for both sides of the suction box.

Cantilever System for Suction Roll

The set of the cantilever system is composed of supports, accessory shoe and traction spindles made in carbon steel to enable the suspension of the roller on the control side for changing the screen.

Lub system bearings:

Made of gray cast iron GG-25 with covers and mazes to prevent water from entering the inner part of the bearings.

The labyrinths are made within a clearance that allows the roller to be lifted on the control side to change the screen.

Lubrication system with connections installed on the front bearing, allowing lubrication through a single point (control side).

Bearing:

Customer supply (not included in the quotation, must be sent for mounting on the roll).

Assembly and startup supervision

Supervision of assembly and startup of the suction couch roll.

We consider 2 (two) technicians for a period of 3 (three) days,an Engineer technician and a mechanical technician, if a longer period is necessary this will be charged in a subsequent invoice at a man hour cost of R $ 60.00 per hour.

Working Hours: 44 (Forty-four) hours per week, from Monday to Friday, between 7:00 am and 6:00 pm

Overtime from Monday to Saturday with 50% (Fifty percent), increase; Sundays and holidays with 100% (One hundred percent), and the other provisions regarding working hours will be regulated by the Brazilian law in force.

Transportation costs (from Rio do Sul to customer) will be paid by Metal Service for 1 (one) time, if a second time is required, this will be charged to the customer. Food and accommodation expenses will in charge of the customer.

Warranty and technical assistance

Warranty for replacement of parts manufactured by Metal Service and damaged by premature wear or project error Metal Service undertakes to deliver the parts to the customer within 48 hours, and the manufactured parts (reducers, motors, bearings, hydraulic unit; hydraulic or pneumatic cylinders, accessories) damaged by premature wear or project error Metal Service undertakes to deliver parts to the customer within a maximum of 10 days.

1. Quality guaranteed.

2. Competitive price.

3. Fast delivery time.

4. Good after sales service.

5. If anything you need help, we will reply you within 24hours.

6.Technical service with a technical service team

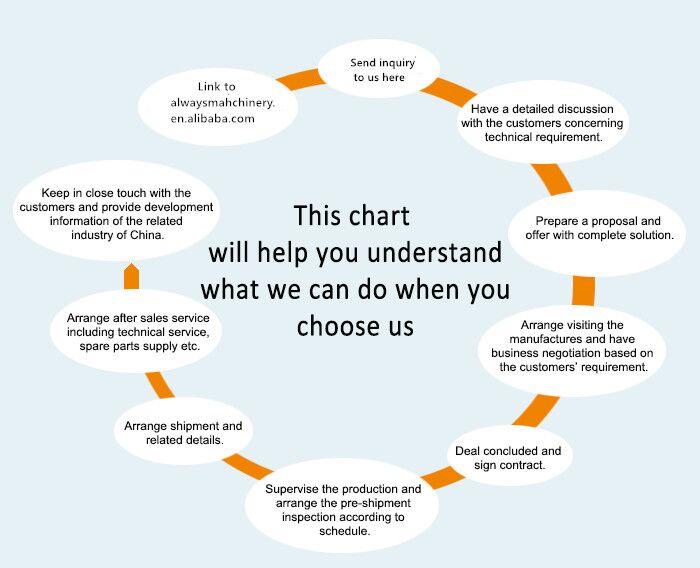

Jinan Always Machinery Co., Ltd. is mainly engaged in exporting Paper machine and providing high quality products and service for foreign customers. Our products mainly exported to Southeast Asia, Africa, Latin America and other more than 10 countries and areas.

We are the key manufacturer specializing in papermaking machinery equipments. Acting as a local representative of manufacture for the last few years, it primarily deals paper machinery spare parts in China. Meantime we have established a good reputation and dependability in the market through our committed services to all concerned.

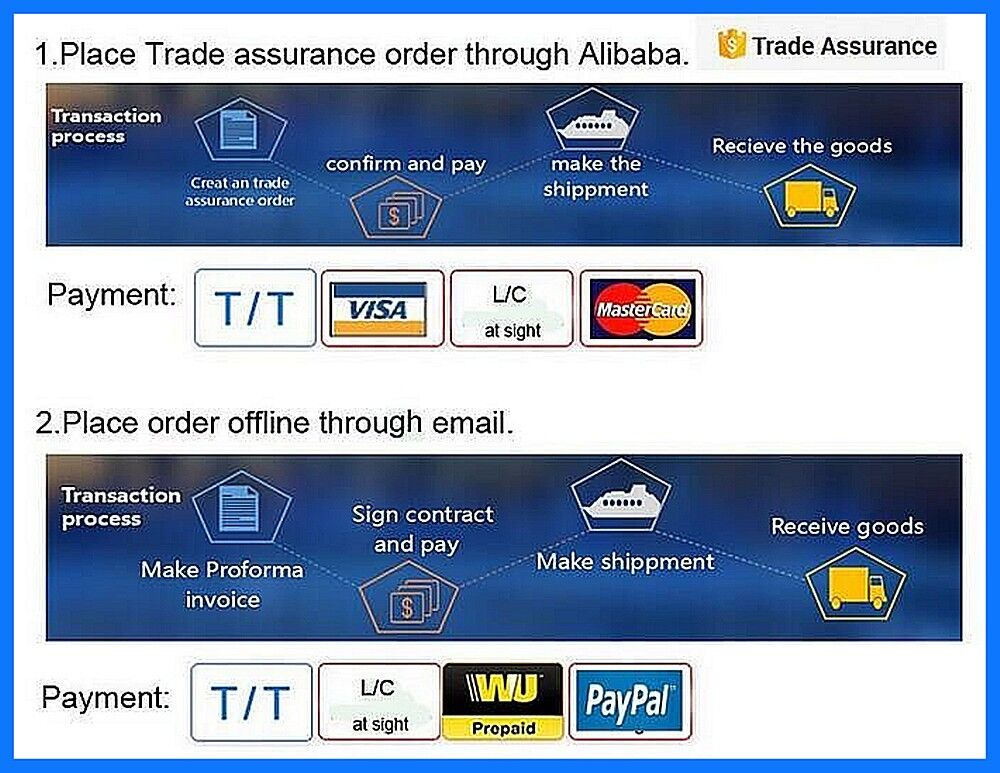

Payment&Contact

1.Q:Can you put my brand name on these products?

A:Yes, we can.

2.Q:What is your usual payment conditions?

A:FOB 30% advanced payment, full payment before delivery, by T/T.

3.Q:Can you provide sample for us?

A:It depends on. If the products you need are standard and we have stock, we will provide.

If not, we can not provide for you immediately. The freight will be payed by buyer.

4.Q:Why choose us?

A:Direct price, gurantee quality, 24H service.

Product Categories : Paper machine parts

Premium Related Products