Industrial Printer Wire Harness

| Min. Order: | 500 Piece/Pieces |

|---|

| Packaging: | Bag/Box/Pallet |

|---|---|

| Productivity: | 10000000pieces/year |

| Brand: | Kable-X |

| Transportation: | Ocean,Land,Air,Express |

| Place of Origin: | China |

| Supply Ability: | 1000000pieces/month |

| Certificate: | UL.IPC620.REACH.ROHS2.0 |

| HS Code: | 8544601200 |

| Port: | Shanghai,Ningbo |

Basic Info

Model No.: 100200200167

Click on the follow link to find out more information: https://www.kable-x-tech.com/printer-wiring-harness/

Company Info

- Company Name: Kable-X Technology (Suzhou) Co., Ltd

- Representative: Zhang Tinghua

- Product/Service: Wiring Harness , Cable Assembly , Custom Wiring Harness , Electrical Wiring Harness , custom cable assembly , Industrial Wiring Harness

- Capital (Million US $): 5000000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 21% - 30%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 5

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: No.2008, Haizang west road, Luzhou Town, Wuzhong district, Suzhou,

- Contact Person: Ms. Angelina Jiang

- Tel: +86-512-65109809

Premium Related Products

Hot Products

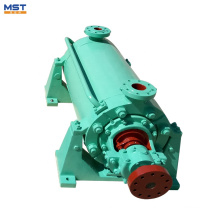

65mqv Centrifugal Vertical Slurry PumpWear Resistant Submersible Slurry Pump with AgitatorAll Kinds of Centrifugal Slurry PumpAicd Proof Centrifugal Vertical Slurry Pump6X4-YG-Gravel Centrifugal Slurry Pump10X8-YA-Heavy Duty Slurry PumpsHigh efficiency and low noise centrifugal dry screw vacuum pumpStainless steel hand operated transfer pumpHot sale High performance Diesel Engine fire fighting centrifugal water pump manufacturershigh pressure water fountain vacuum pumps price china manufacturemini suction electric mine gravel slurry mud sucker pumps specificationDouble suction diesel engine irrigation pumpwater pump variable flow rateYQ cast iron horizontal centrifugal slurry mud pumps machineQJ model deep well 1.5 hp submersible pumpHigh efficiency horizontal multistage centrifugal water pump