All Kinds of Centrifugal Slurry Pump

Basic Info

Model No.: MAHR

Product Description

Characteristics

| ·Type: | ·Media: | ·Application: |

| centrifugal | slurry | macerator |

| ·Other characteristics: | ·Flow rate: | ·Pressure |

| horizontal | Min.:0m3/h | Min.: 0Pa |

| Max.: 5000m3/h | Max.: 2020000Pa | |

| ·Head | ||

| Min: 0m | ||

| Max: 73m |

Description

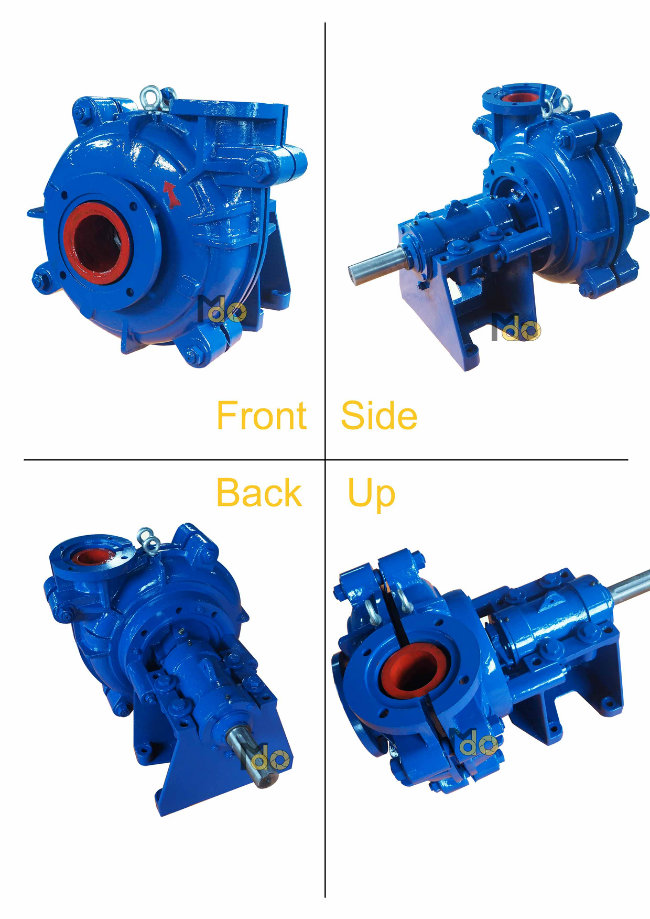

The Modo MAH series pumps are cantilevered, horizontal centrifugal slurry pumps designed for handling abrasive, high density slurries in a wide range of applications.

MAH pumps are manufactured to be interchangeable with the most common Slurry Pump designs and feature a wide range of options. MAH Slurry Pumps provide rugged performance and reliability in the most demanding slurry pumping applications.

Features

Bearing assembly- large diameter shaft with short overhang contributes to long bearing life.

Liners - easily replaceable liners are bolted, not glued to the casing for positive maintenance.

Casing - casing halves of cast or ductile iron provide high operating pressure capabilities.

Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

Throat bush - wear IS reduced and maintenance simplified by the use of tapered.

Application

Transfer of abrasives and high density slurries in:

Mining

Metallurgical Processing

Civil Construction

Heavy Industry

Processing

Details

Pump Parts Material

Rubber Pump | Metal Pump | ||||

No. | Part Description | Material Specification | No. | PartDescription | Material Specification |

1 | Base | Cast Iron | 1 | Base | Cast Iron |

2 | Shaft | 4140 High Tensile Steel* | 2 | Shaft 4140 | High Tensile Steel* |

3 | Bearing Assembly | Timken (Cast Iron Body) | 3 | Bearing Assembly | Timken (Cast Iron Body) |

4 | Shaft Sleeve | 420 Stainless Steel | 4 | Shaft Sleeve | 420 Stainless Steel |

5 | Pump Casing | Cast Iron | 5 | Pump Casing | Cast Iron |

6 | Frame Plate | Liner Insert Rubber | 6 | Frame Plate | Liner 27% Chrome White Iron |

7 | Cover Plate | Liner Rubber | 7 | Volute Liner | 27% Chrome White Iron |

8 | Impeller | Rubber Coated High Tensile Steel | 8 | Impeller 27% | Chrome White Iron |

9 | Throat Bush | Rubber | 9 | Throat Bush | 27% Chrome White Iron |

10 | Cover Plate | Cast Iron | 10 | Joint Rings | Rubber |

11 | Stuffing Box | Cast Iron | 11 | Cover Plate | Cast Iron |

12 | Expeller | 27% Chrome White Iron | 12 | Stuffing Box | Cast Iron |

13 | Expeller | Ring Natural Rubber | 13 | Expeller | 27% Chrome White Iron |

14 | Bolts | Zinc Plated Steel | 14 | Expeller Ring | Natural Rubber |

15 | O-rings | Nitrile Rubber | 15 | Bolts | Zinc Plated Steel |

16 | Seals | Rubber | 16 | O-rings | Nitrile Rubber |

17 | Seals | Rubber | |||

FAQ

FAQA: What kind of company you are?

Q: We are centrifugal pump manufacture located in Boy Town, Baoding, China, with more than 20years experiences. We were gaining good reputation among our customers for our professional, warm and thoughtful service. Because we know that a long terms business based on the quality control, price, packing, delivery time etc.

A: What's the quality assurance you provided and how do you control quality?

Q: Established a procedure to check products at all stages of the manufacturing process: Casting, Heat treatment, Machining, Assembly, and Testing.

Q: Can you install the motor or diesel engine with the pump for us?

A: yes, we can, it's no problem, and we are experienced in this.

Q: What's your MOQ?

A: Trial sample order is OK.

Q: What are your payment terms?

A: T/T, L/C, D/P, D/A......

Q: What certificates do you have?

A: CE, ISO 2008, UL.....

Q: How about the warranty?

A: One year warranty for pumps, it depends on other pump working condition details.

Q: What is the delivery time?

A: 15-30 days according to customer quantities.

Q: Can you do OEM brand?

A: Yes, Welcome.

Q: What information should I offer to get pump solution?

1, Material:

2, Head: m

3, Flow: m3/h

4, Medium size: mm

5, Particle shape (smooth or sharp):

6, Medium pH level:

7, Temperature:

8, Drive type:

9. Power supply:

Contact me for detail offer with curve and drawing!

Zero Zuo

Mob: +86 158 3083 2060

Tel: +86 312 8929296

Fax: +86 312 3085383

Contact us if you need more details on Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vertical Slurry Pump、Submersible Slurry Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : MAH Horizontal Slurry Pump