no clogging 250mm discharge large flow cast iron submersible waste water pump

Product Description

no clogging 250mm discharge large flow cast iron submersible waste Water Pump

Pump overview

submersible waste water pumps is mainly used for municipal works, industrial buildings,hotels,hospitals,civil air defense,mines etc. Trades to drain off the sewage, waste water, rainwater and living water in cities containing solid grains and various long fabrics.

Model No | 250WQ600-25-75 |

Flow(m3/h) | 600 |

Head(m) | 25 |

Stage | Single |

Outlet Dia.(mm) | 250 |

Pump casing | cast iron |

Pump impeller | cast iron |

Shaft | 45# steel |

Shaft seal | Mechanical seal |

Motor power | 75kw |

Pump Advantage

●The impeller adopts particular large channel structure, so the drain capacity has been improved greatly, it can effecitively pass the solid grain whose diameter is about 50% of the pump caliber.

●To improve the application safety this pump can be fixed with various protective devices according to the consumer's requirements, including: stator winding temperature-rise protection, bearing temperature-rise protection, oil chamber water-leakage protection etc devices.

●It adopts inner self-flow circulation system. The motor is cooled by liquid, so it is safer o use. At the same time, the electric pump can be installed in dry and fixed form by this structure.

The installation conditions of the submersible Sewage Pump are simple, and the flow coverage is large. It is one of the most commonly used lifting equipment in water treatment projects, especially in small and medium-sized projects. There are mainly two common installation methods for submersible sewage pumps: coupled installation and mobile installation.

1. Coupling installation is to connect the pump to the pipeline through a coupler, and it is convenient to disconnect the pump from

the outlet pipeline. The pump can be lifted by the lifting device when it is overhauled. Coupling installation is suitable for

submersible sewage pumps of various specifications and is the most commonly used installation method for submersible sewage pumps.

The coupler is supplied as a complete set by the equipment manufacturer.

2. Mobile installation means that the pump outlet pipeline is directly connected to the surface of the water through a hose, and the submersible sewage pump is self-reset at the bottom of the pool or hung on the lifting device through iron chains. The mobile installation does not require a coupler and the bottom of the pool to be fixed, which is easy to move and can be lifted together with the pipeline during maintenance. At the same time, due to the installation method, it is difficult to bear a large torque, which is only suitable for small submersible sewage pumps.

It is especially suitable for underground water pumping in rural areas, field drainage and irrigation, garden irrigation and household water use, and can also be used to remove industrial water accumulation, water supply and drainage for construction and breeding industry.

SHIJIAZHUANG MILESTONE ENGINEERING & MANUAFCTURING CO.,LTD.

Milestone Engineering & Manufacturing is one of the leading private indenting firms of China having 10 years of experience in Mining, Fluid Transportation and Fire Emergency Field. It works on design theory of slurry pump and water pump, experimental researches of pump performance wear mechanism and new products developing, and involves in research, design, manufacturing and sales.

Our service - professional attentive.

* Perfect Quality Control-- We own professional quality management and process inspection team

* Fast High Quality Service--In the process of service,the demands of all customers can be solved quickly and effectively.

* Supply Support Capacity--We ensures the products with good quality,suffcient quantity and diversification.

* Excellent Cost Performance--Provide the most excellent products,the most favorable price and the most perfect service to all customers.

Q1: What is your product range?

A:Centrifugal pump includes slurry pump, gravel pump, clean water pump, submersible sewage pump, Chemical Pump, self-priming pump and diesel engine pump.

Q2: What's your MOQ , payment term and lead time?

A:MOQ for centrifugal pump is 1 set.

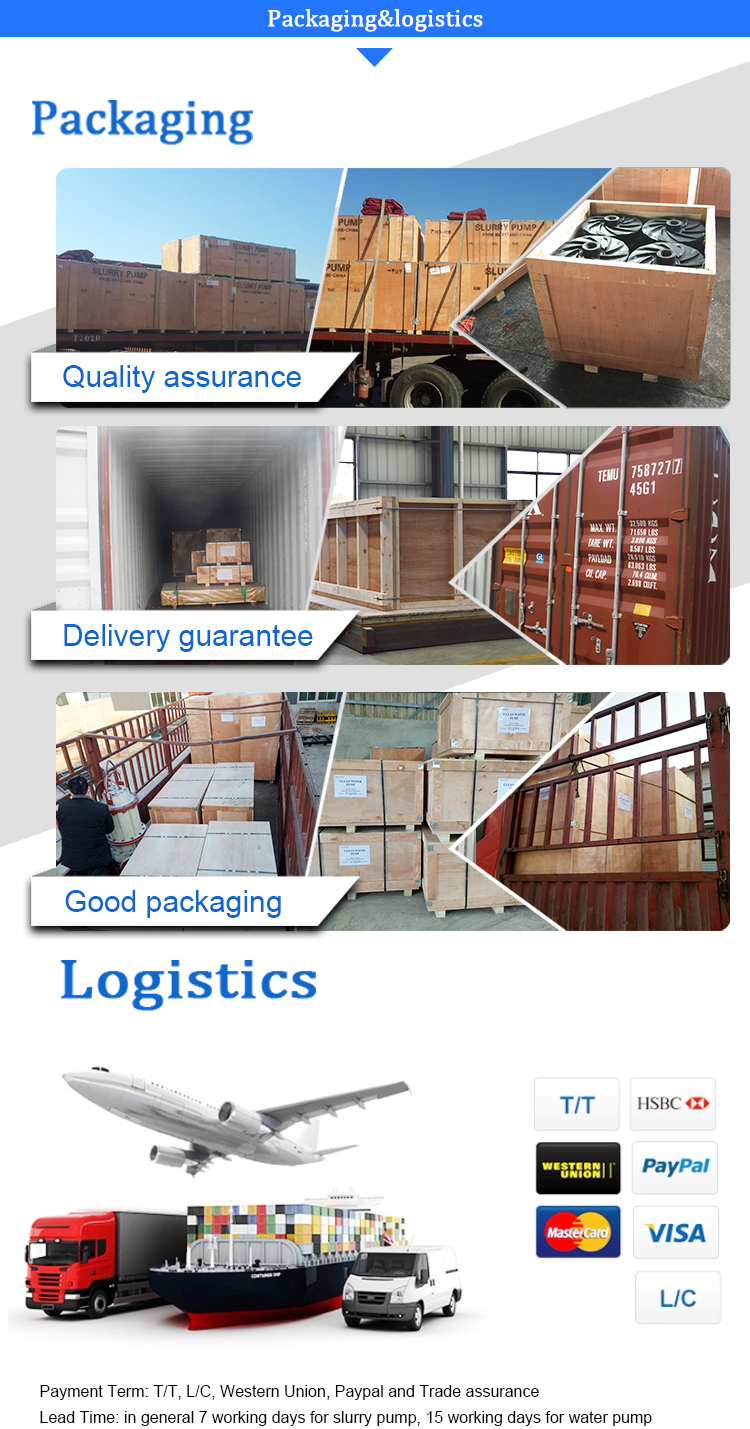

Q3: What payment methods are supported?

A: Payment Term: T/T, L/C, Western Union, Paypal and Trade assurance.

Q4: How long is the lead time?

A:In general 7 working days for slurry pump, 15 working days for waste water pump.

Q5: What information I need to offer for quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Is OEM parts available ?

A:Yes, please send me the detailed drawing. Different materials is available.

Product Categories : Sewage Pump > Sewage Pump

Premium Related Products